Dyfais Effaith Profwr Caledwch

Dyfais Effaith Profwr Caledwch

Gwahanol fathau o Ddychymyg Effaith

|

Deunydd |

Dull caledwch |

Dyfais effaith |

|||||

|

D / DC |

D + 15 |

C |

G |

E |

DL |

||

|

Dur a dur bwrw |

HRC |

17.9 ~ 68.5 |

19.3 ~ 67.9 |

20.0 ~ 69.5 |

22.4 ~ 70.7 |

20.6 ~ 68.2 |

|

|

HRB |

59.6 ~ 99.6 |

47.7 ~ 99.9 |

37.0 ~ 99.9 |

||||

|

HRA |

59.1 ~ 85.8 |

61.7 ~ 88.0 |

|||||

|

HB |

127 ~ 651 |

80 ~ 638 |

80 ~ 683 |

90 ~ 646 |

83 ~ 663 |

81 ~ 646 |

|

|

HV |

83 ~ 976 |

80 ~ 937 |

80 ~ 996 |

84 ~ 1042 |

80 ~ 950 |

||

|

HS |

32.2 ~ 99.5 |

33.3 ~ 99.3 |

31.8 ~ 102.1 |

35.8 ~ 102.6 |

30.6 ~ 96.8 |

||

|

Dur morthwyl |

HB |

143 ~ 650 |

|||||

|

Dur offeryn gwaith oer |

HRC |

20.4 ~ 67.1 |

19.8 ~ 68.2 |

20.7 ~ 68.2 |

22.6 ~ 70.2 |

||

|

HV |

80 ~ 898 |

80 ~ 935 |

100 ~ 941 |

82 ~ 1009 |

|||

|

Dur gwrthstaen |

HRB |

46.5 ~ 101.7 |

|||||

|

HB |

85 ~ 655 |

||||||

|

HV |

85 ~ 802 |

||||||

|

Haearn bwrw llwyd |

HRC |

||||||

|

HB |

93 ~ 334 |

92 ~ 326 |

|||||

|

HV |

|||||||

|

Haearn bwrw nodular |

HRC |

||||||

|

HB |

131 ~ 387 |

127 ~ 364 |

|||||

|

HV |

|||||||

|

Alwminiwm cast aloion |

HB |

19 ~ 164 |

23 ~ 210 |

32 ~ 168 |

|||

|

HRB |

23.8 ~ 84.6 |

22.7 ~ 85.0 |

23.8 ~ 85.5 |

||||

|

Pres (aloion copr-sinc) |

HB |

40 ~ 173 |

|||||

|

HRB |

13.5 ~ 95.3 |

||||||

|

Efydd (aloion copr-alwminiwm / tun copr) |

HB |

60 ~ 290 |

|||||

|

Copr gyr aloion |

HB |

45 ~ 315 |

|||||

|

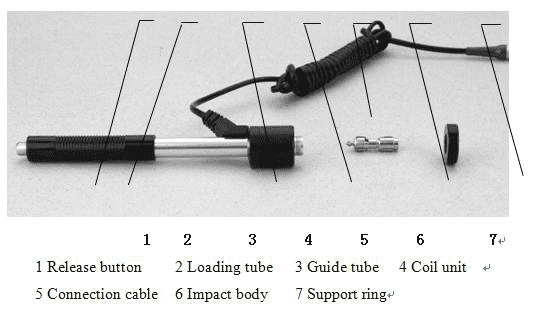

Anghonfensiynol dyfeisiau effaith |

DC (D) / DL |

D + 15 |

C |

G |

E |

|

|

Effeithio ar egni Màs yr effaith corff |

11Mj

5.5g / 7.2g |

11mJ

7.8g |

2.7mJ

3.0g |

90mJ

20.0g |

11mJ

5.5g |

|

| Awgrym prawf Caledwch Diamedr y domen brawf Deunydd y domen brawf |

1600HV 3mm Carbid twngsten |

1600HV 3mm Carbid twngsten |

1600HV 3mm Carbid twngsten |

1600HV 5mm Carbid twngsten |

5000HV 3mm synthetig diemwnt |

|

|

Diamedr dyfais effaith Dyfais effaith Hyd Dyfais effaith Pwysau |

20mm

86 (147) / 75mm

50g |

20mm

162mm

80g |

20mm

141mm

75g |

30mm

254mm

250g |

20mm

155mm

80g |

|

|

Max. caledwch workpiece |

940HV |

940HV |

1000HV |

650HB |

1200HV |

|

|

Garwder cymedrig arwyneb workpiece y Ra |

1.6μm |

1.6μm |

0.4μm |

6.3μm |

1.6μm |

|

|

Munud. pwysau'r sampl Mesur yn uniongyrchol Angen cefnogaeth yn gadarn Angen cyplu'n dynn |

> 5kg 2 ~ 5kg 0.05 ~ 2kg |

> 5kg 2 ~ 5kg 0.05 ~ 2kg |

> 1.5kg 0.5 ~ 1.5kg 0.02 ~ 0.5kg |

> 15kg 5 ~ 15kg 0.5 ~ 5kg |

> 5kg 2 ~ 5kg 0.05 ~ 2kg |

|

|

Munud. trwch y cyplydd sampl yn dynn Trwch min.layer ar gyfer caledu wyneb |

5mm

≥0.8mm |

5mm

≥0.8mm |

1mm

≥0.2mm |

10mm

≥1.2mm |

5mm

≥0.8mm |

|

|

Maint indentation domen |

||||||

|

Caledwch 300HV |

Indentation diamedr |

0.54mm |

0.54mm |

0.38mm |

1.03mm |

0.54mm |

|

Indentation dyfnder |

24μm |

24μm |

12μm |

53μm |

24μm |

|

|

Caledwch 600HV |

Indentation diamedr |

0.54mm |

0.54mm |

0.32mm |

0.90mm |

0.54mm |

|

Indentation dyfnder |

17μm |

17μm |

8μm |

41μm |

17μm |

|

|

Caledwch 800HV |

Indentation diamedr |

0.35mm |

0.35mm |

0.35mm |

– |

0.35mm |

|

Indentation dyfnder |

10μm |

10μm |

7μm |

– |

10μm |

|

|

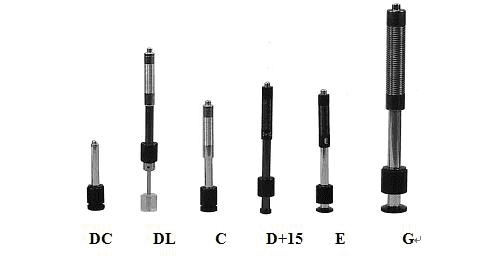

Math o ddyfais effaith sydd ar gael |

D: Prawf cyffredinol

DC: Prawf silindrog twll neu wag

DL: Rhigol cul main neu brawf twll

|

D + 15: groove neu arwyneb reentrant |

C: rhannau bach, ysgafn, tenau neu arwyneb haenen hardend |

G: dur wyneb mawr, trwchus, trwm neu arw |

E: deunydd caledwch super uchel |

|

|

Math o Ddychymyg Effaith |

Pellter canol y ddau fewnoliad |

Pellter canol y indentation i ymyl sampl |

|

Dim llai na (mm) |

Dim llai na (mm) |

|

|

D 、 DC |

3 |

5 |

|

DL |

3 |

5 |

|

D + 15 |

3 |

5 |

|

G |

4 |

8 |

|

E |

3 |

5 |

|

C |

2 |

4 |